AI for Engineering

AI for Engineering, an active topic for Michelin.

Looking back at 2022, we have been communicating on it on different channels, but not on that tech blog. Let’s do it now before it gets outdated!

In the data transformation at Michelin, we love meshes [see data mesh], and Artificial Intelligence is an asset we are developing using our data mesh principle. The target is to develop AI technologies to augment our capabilities in manufacturing, research and development, connected mobility, supply-chain, customer experience. Each of those domains are contributing to our AI capabilities and assets. This AI expertise distributed across the company is the core of our center of excellence.

Some of what we do on those domains could be of interest for you, readers of this IT blog. Depending on your interest on this article, more could come...

AI for Product Development

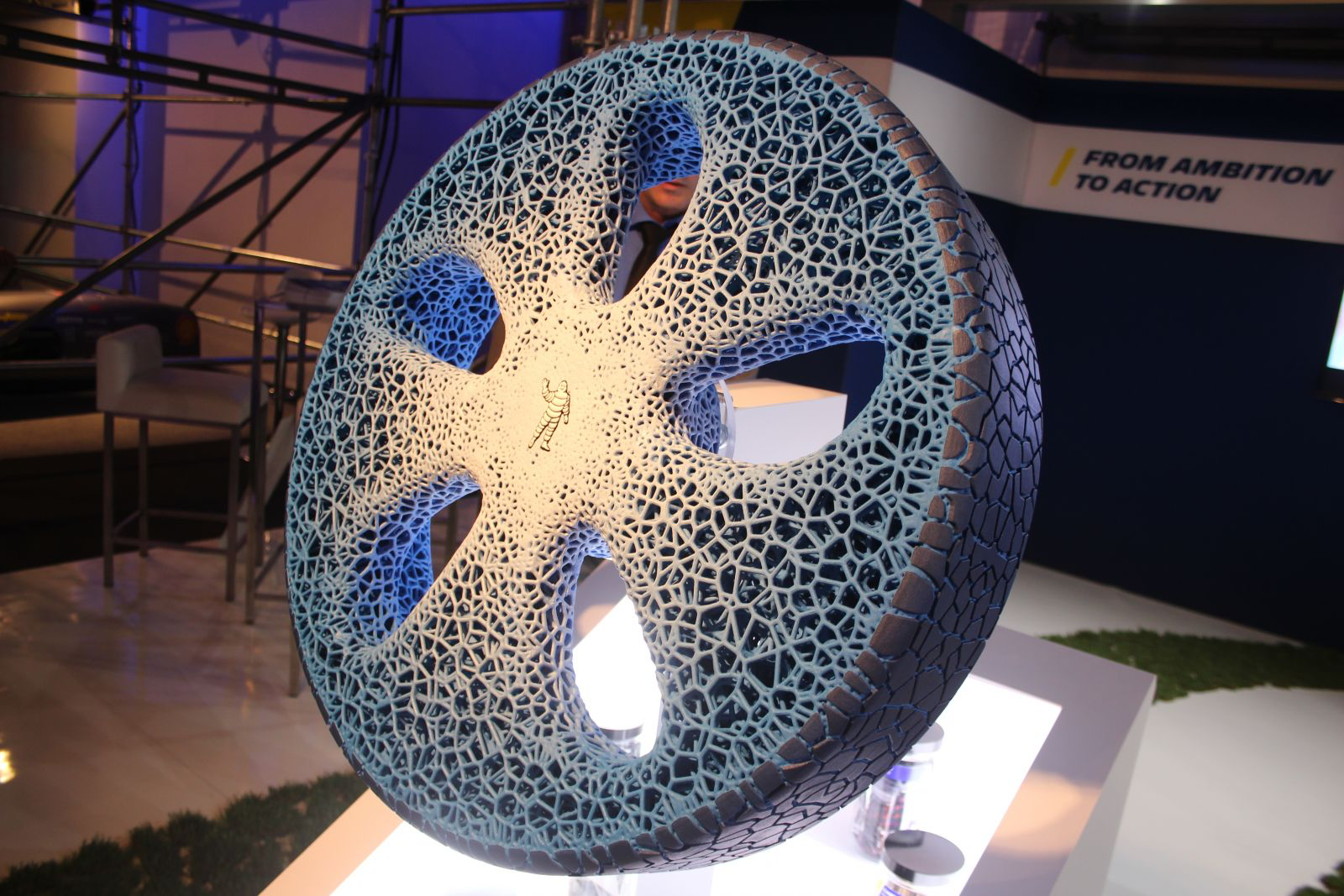

So what about AI in product (here, the product is the tire ;o)) development.

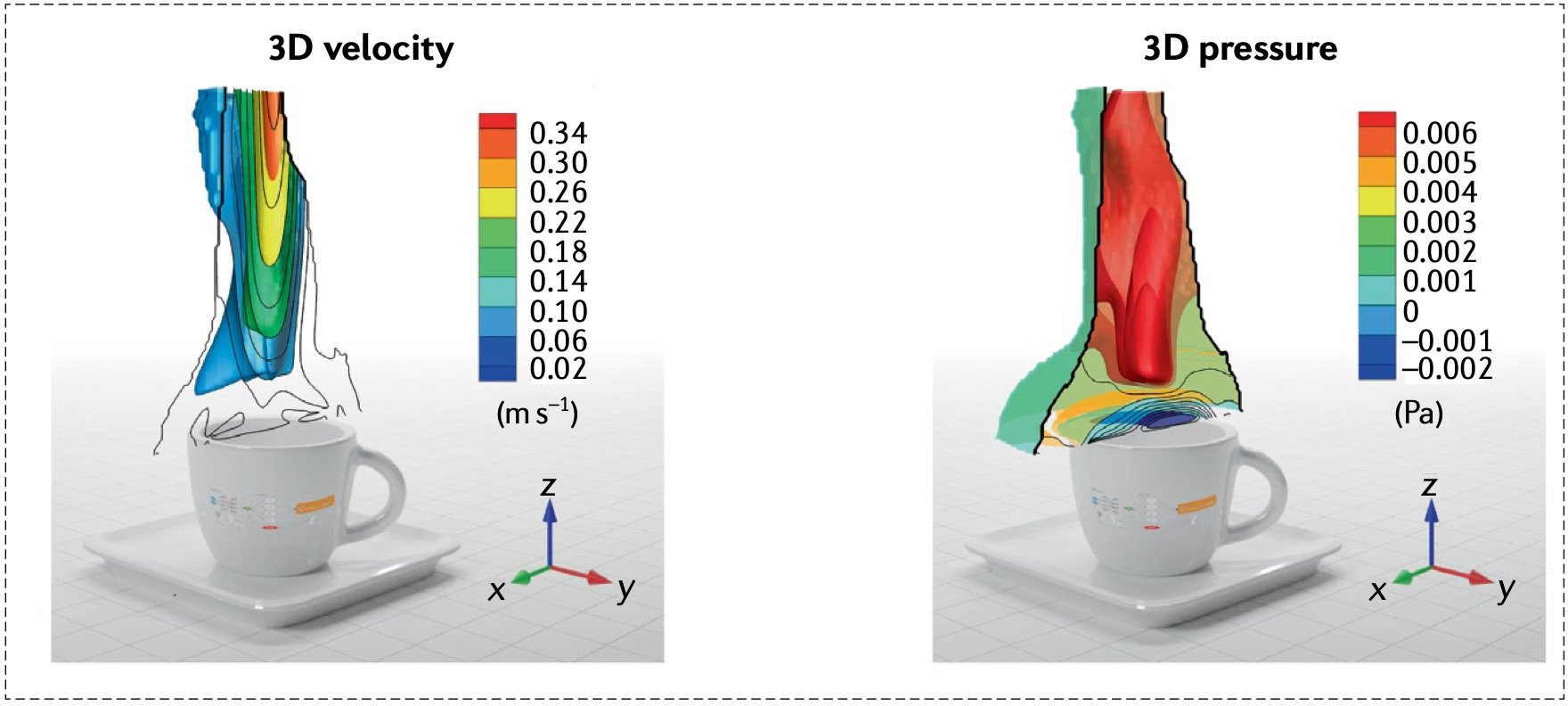

Using data and applied mathematics has always been a part of product R&D. At Michelin in particular, the R&D department has more than 30 years of simulation history, modeling everything from how molecules in materials interact with each other’s to how tires interact with vehicle and ground to understand how it is making noise, gripping on snow, wearing, being fuel efficient, and more (each application having their own needs). Any of these performance assessments is another possibility for applying AI in product development. So, how can machine learning and product experts work together to make these applications a reality?

I have been invited by Léo Dreyfus-Schmidt, VP of Research at Dataiku and head of the AI Lab, to get into details of that story. Here is the link to watch the full video of that session.

"We've been working on trying to put some machine learning models behind [the data], and it's working ... Of course, there's a lot of work to gather the data, to make sure that we are using the right parameters, the right features, etc., but the concept is working. But then, there are a lot of questions regarding the quality of these models. If they can help us to, let's say, have new ideas, that's fine. But the target or the goal would be to homologate the product through these sorts of models. It means that we go to ... any car manufacturer and we say, ok, our model is predicting this, and you can trust us. So that's the ultimate goal."

So, from that quote, you got the gist: machine learning is working, and pretty well!

But to move from being opportunistic i.e. using past data to accelerate discovery to driving data to generate knowledge, through models, on which we learn and validate, we still have a few topics to address properly.

To reach that target, we are developing our AI 4 Engineering strategy through the following 4 points.

We need better models

The world of engineering is not a big data world, each experiment is costly. At the same time, we have access to a lot of physics knowledge from experienced engineers and associated simulation systems. Given such cost constraint and our knowledge assets, the key is to build models that use the deep knowledge and expertise to move toward hybrid simulation for accuracy and acceleration. Coming from a simulation group, combining it with AI is largely developed at Michelin. We talk the benefit of that hybrid approach with other industrial companies in this usine nouvelle article (in french and behind paywall).

Beyond efficiency, simulation generates massive 3D datasets, that are very interesting to work with.

But what is a better model?

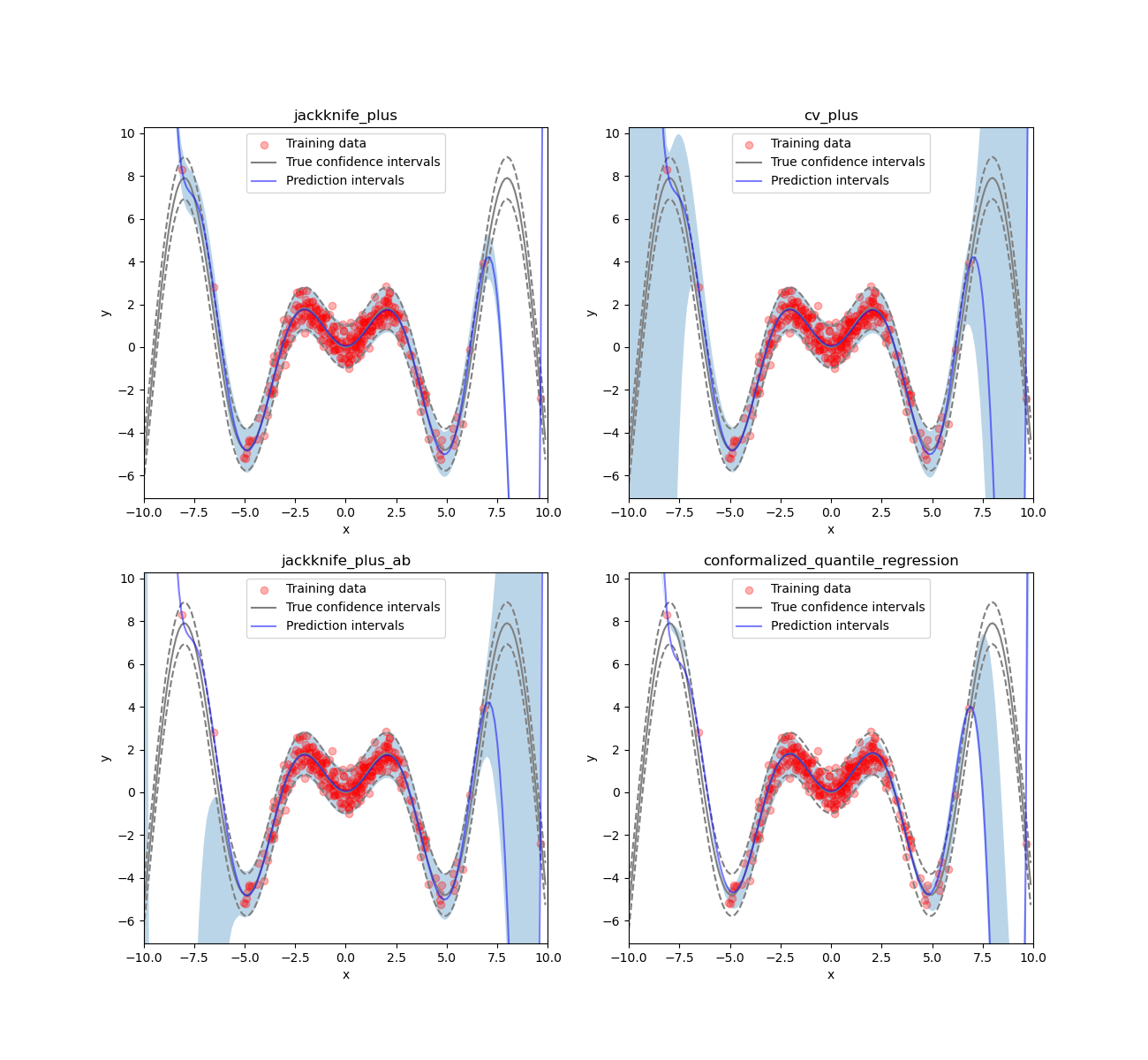

We assume physically informed models are better, but we certainly need to define the better in the proper way. Engineers require trustworthy AI solutions to make design decisions. For us, this comes with uncertainty and validity domain assessment. Because it is a very active research topic, we need to pick and choose robust solutions carefully as it impacts our risk evaluation. One example of initiative in that field is the evaluation of the state of art for uncertainty estimators in machine learning. It has been conducted with Quantmetry through a collaborative research project. Results are capitalized within the Mapie open source project and could be interesting for you. Contributions are always welcome !

Coming up with solutions!

Once you have entered the trusting zone of engineers, they won't want predictions for all possible combinations any more — they will be looking for solutions ! AI teams need to provide a way to quickly assess the best tradeoffs inside a defined parameters domain. You may say that it's classic optimization, but this is challenging when the design space is not properly defined – for example when many constraints are non-explicit. To overcome such constraints, Generative approaches are investigated to learn the design space from existing data and explore it beyond. See this NIPS paper that illustrates some of our ideas to generate tabular data that is representing material recipes.

Is this true?!

We aim to anticipate internal understanding of what is a tire performance ; but is the predicted performance related to the way customers are seeing the performance? This means assessing solutions' robustness with respect to real use uncertainty — including manufacturing and customer usage — to predict real-life performance (moving toward digital twins). By the accessibility of real-life customer data, that last point is closing the loop to get more realistic performance assessment.

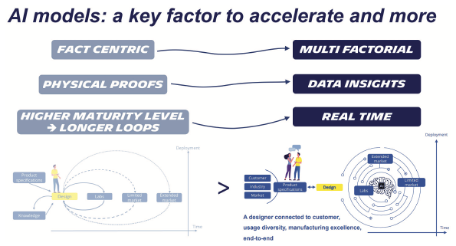

To end on a point of view from our design community, the target is to accelerate our move from a fact-centric & independent validation loop to a combination of multi-factorial data centric models decision making.

If you are interested in discussing those different topics, do not hesitate to ping us. We will come back later with some technical details on the different chapter if the blog monitoring tells us you like it.